In this article, we will be discussing the importance of wearing appropriate clothing when using power tools. We will explore the potential dangers of improper attire and highlight the key factors to consider when choosing your work outfit. By the end of this article, you will have a better understanding of how to stay safe and comfortable while operating power tools, ensuring a successful and injury-free work experience.

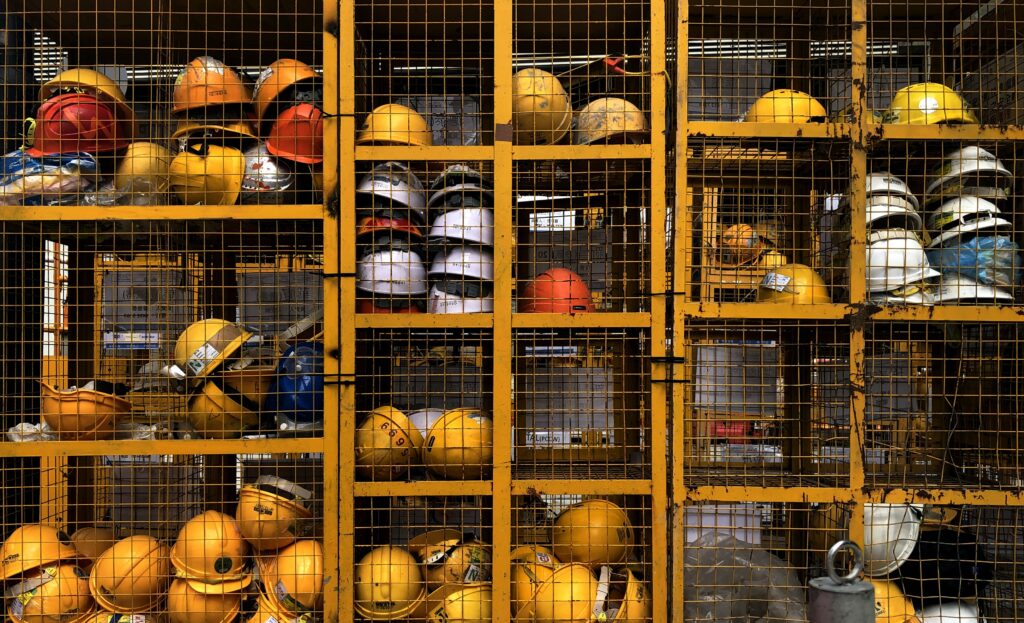

Safety Equipment

When working with power tools, it is essential to prioritize safety. One way to do that is by wearing the appropriate safety equipment. In this article, we will discuss the different types of safety equipment that should be worn when using power tools.

Protective Clothing

Protective clothing plays a crucial role in keeping you safe while operating power tools. It helps protect your body from potential hazards such as flying debris or accidental spills. Let’s take a look at some of the most common types of protective clothing:

Coveralls

Coveralls are one-piece garments that cover the entire body from neck to ankle. They provide full-body protection and are commonly worn in hazardous work environments. When choosing coveralls, make sure they are made from a durable and flame-resistant material.

Long-sleeved Shirts

Wearing long-sleeved shirts provides additional protection to your arms while working with power tools. It helps prevent cuts, burns, or any other injuries that may occur during the operation. Opt for shirts made from a thick and sturdy fabric.

Long Pants

Similar to long-sleeved shirts, long pants offer protection to your legs. They help minimize the risk of accidental cuts or burns when working with power tools. Choose pants that fit well and are made of durable materials like denim or canvas.

Proper Fit

No matter what type of protective clothing you choose, it is essential to ensure a proper fit. Ill-fitting clothing can hinder your movement and increase the risk of accidents. Always check the size and try on the clothing before purchasing. It should allow you to move comfortably without any restrictions.

Safety Shoes

Protecting your feet is equally important when working with power tools. Safety shoes provide the necessary support and protection to your feet, minimizing the risk of accidents. Let’s take a look at some features to consider when choosing safety shoes:

Steel Toe Boots

steel toe boots are essential in protecting your toes from potential crushing hazards. They are reinforced with a steel cap at the front, providing adequate protection if heavy objects were to fall on your feet. Look for boots that meet the required safety standards and provide a comfortable fit.

Slip-resistant Soles

Power tools are often used in environments where spills or wet surfaces are common. Safety shoes with slip-resistant soles help prevent slips and falls, reducing the risk of injuries. Ensure that the shoes have good traction and provide stability on different surfaces.

High Ankle Support

Power tools can sometimes be heavy, and improper handling can lead to sprains or twists in your ankle. Safety shoes with high ankle support provide stability and minimize the risk of injuries. Look for shoes with padded ankle collars and sturdy construction.

Safety Glasses

Eye protection is another crucial aspect of staying safe while using power tools. Safety glasses shield your eyes from potential hazards such as flying debris, dust particles, or sparks. Here are some features to consider when choosing safety glasses:

Impact-resistant Lenses

When working with power tools, there is always a risk of flying debris or projectiles. Safety glasses with impact-resistant lenses provide a barrier against these hazards, reducing the risk of eye injuries. Look for glasses that meet safety standards and have clear lenses for maximum visibility.

UVA/UVB Protection

Some power tools generate bright light or emit harmful UV rays. Safety glasses with UVA/UVB protection help shield your eyes from these harmful rays, reducing the risk of long-term eye damage. Make sure the glasses provide adequate protection against both UVA and UVB rays.

Wrap-around Style

Safety glasses with a wrap-around style provide better coverage and protect your eyes from all angles. This style prevents debris from entering the sides of the glasses and ensures maximum protection. Look for glasses with an adjustable nose piece and comfortable temple arms for a secure fit.

Ear Protection

Power tools can generate high levels of noise that can be damaging to your hearing. It is important to protect your ears from prolonged exposure to loud sounds. Here are two common types of ear protection:

Earplugs

Earplugs are small, foam or silicone inserts that fit inside your ears, creating a barrier against noise. They are inexpensive, disposable, and easy to carry around. Earplugs come in various sizes and shapes, so it’s crucial to find the ones that fit your ears properly for maximum effectiveness.

Earmuffs

Earmuffs are another type of ear protection that covers your entire ears. They consist of two ear cups connected by a headband. Earmuffs provide a higher level of noise reduction compared to earplugs and are more suitable for prolonged exposure to loud sounds. Look for earmuffs with adjustable headbands and comfortable padding.

Noise Reduction Rating

When choosing ear protection, consider the noise reduction rating (NRR). The NRR indicates how much the earplugs or earmuffs can reduce the noise level. The higher the NRR, the more effective the ear protection will be in blocking out loud sounds. Choose the ear protection with the appropriate NRR for your specific needs.

Types of Power Tools

Now that we have discussed the importance of safety equipment let’s move on to the different types of power tools that you may encounter in your work. Power tools can be classified into three main categories: handheld power tools, Stationary power tools, and pneumatic power tools.

Handheld Power Tools

Handheld power tools are portable and can be operated with one hand. They are commonly used for various tasks such as drilling, sanding, cutting, and grinding. Some common examples of handheld power tools include:

Drills

Drills are versatile power tools used for creating holes in different materials. They are equipped with a rotating drill bit and can be used for various applications such as woodworking, metalworking, or masonry.

Sanders

Sanders are power tools used for smoothing surfaces by abrasion. They are ideal for removing paint or varnish, shaping wood, or giving final finishing touches to a project. Sanders come in different types such as orbital sanders, belt sanders, or detail sanders.

Grinders

Grinders are powerful tools used for cutting, grinding, or polishing different materials. They are commonly used in metalworking or construction projects. There are various types of grinders available, including angle grinders and bench grinders.

Saws

Saws are power tools used for cutting through materials such as wood or metal. They come in different types, including circular saws, jigsaws, or reciprocating saws. Saws are versatile tools and can be used for a wide range of cutting applications.

Stationary Power Tools

Stationary power tools are larger and are meant to be mounted or placed on a workbench or stand. They provide stability and accuracy for more precise and controlled operations. Some common examples of stationary power tools include:

Table Saw

A table saw is a powerful woodworking tool used for making straight cuts in wood. It consists of a circular saw blade mounted on a table with a sliding surface. Table saws are versatile and can be used for various woodworking tasks.

Bandsaw

A bandsaw is a saw with a long, continuous blade that runs on two wheels. It is primarily used for making curved cuts or intricate designs in wood or metal. Bandsaws are commonly found in woodworking or metalworking shops.

Jointer

A jointer is a woodworking tool used for flattening and smoothing the edges of a board. It is particularly useful in creating straight and square edges before joining multiple pieces of wood together.

Planer

A planer is a woodworking tool used for smoothing and flattening the surface of a board. It is used to create a consistent thickness across the entire length of the board and is essential for achieving precise and uniform results.

Pneumatic Power Tools

Pneumatic power tools, also known as air tools, are powered by compressed air. They are lightweight, powerful, and commonly used in construction or automotive industries. Some common examples of pneumatic power tools include:

Air Compressor

An air compressor is a machine that generates and stores compressed air. It is the main source of power for pneumatic tools. Air compressors are available in different sizes and capacities depending on the specific application.

Nail Gun

A nail gun, also known as a nailer, is a power tool used for driving nails into various materials. It is commonly used in construction or carpentry projects to save time and effort compared to manual hammering.

Paint Sprayer

A paint sprayer is a power tool used for applying paint or other coatings to surfaces quickly and evenly. It is commonly used in painting projects that require a large area to be covered efficiently.

Choosing the Right Clothing

In addition to safety equipment, choosing the right clothing is also crucial when using power tools. The right clothing can provide additional protection and comfort during your work. Let’s discuss some factors to consider when selecting your work attire:

Coveralls

Coveralls are one of the most popular choices for work attire in various industries. They offer full-body protection and help prevent your normal clothes from getting dirty or damaged. When selecting coveralls, make sure they are made from a durable and flame-resistant material for enhanced safety.

Long-sleeved Shirts

Wearing long-sleeved shirts provides extra protection for your arms. They help shield your skin from cuts, burns, and exposure to harmful substances. Choose shirts made from a thick and sturdy fabric that can withstand the demands of your work environment.

Long Pants

Similar to long-sleeved shirts, long pants offer protection to your legs. They help shield your skin from cuts, abrasion, and exposure to various hazards. Look for pants that fit well and are made of durable materials like denim or canvas for maximum durability and comfort.

Proper Fit

Ensuring the proper fit of your work clothing is essential for your safety and comfort. Ill-fitting clothing can hinder your movement and increase the risk of accidents. Always check the size and try on the clothing before purchasing. It should allow you to move comfortably without any restrictions.

Selecting Safety Shoes

Safety shoes are a critical component of your work attire when using power tools. They provide protection and support to your feet, reducing the risk of injuries. Here are some features to consider when selecting safety shoes:

Steel Toe Boots

Steel toe boots are an essential type of safety footwear. They have a reinforced steel cap at the front that protects your toes from potential crushing hazards. Look for boots that meet the required safety standards and provide a comfortable fit. Make sure the steel toe is covered with a protective layer to prevent any discomfort or injuries.

Slip-resistant Soles

Safety shoes with slip-resistant soles are crucial for maintaining stability and preventing slips and falls. Most work environments involving power tools are prone to spills, wet surfaces, or uneven terrain. Ensure that the shoes have good traction and provide stability on different surfaces.

High Ankle Support

Power tools can be heavy, and improper handling can lead to sprains or twists in your ankles. Safety shoes with high ankle support provide stability and minimize the risk of injuries. Look for shoes with padded ankle collars and sturdy construction to ensure a secure and comfortable fit.

Importance of Safety Glasses

Your eyes are incredibly vulnerable when working with power tools, making safety glasses an indispensable safety accessory. They protect your eyes from debris, splashes, or any other potential hazards. Let’s discuss some features that make safety glasses essential:

Impact-resistant Lenses

Power tools often generate flying debris, which can cause serious eye injuries if they come in contact with your eyes. Safety glasses with impact-resistant lenses provide a barrier against these hazards. Look for glasses that comply with safety standards and have clear lenses for maximum visibility.

UVA/UVB Protection

Some power tools generate bright light or emit harmful ultraviolet (UV) rays. Safety glasses with UVA/UVB protection help shield your eyes from these harmful rays, reducing the risk of long-term eye damage. Make sure the glasses offer adequate protection against both UVA and UVB rays.

Wrap-around Style

Safety glasses with a wrap-around style provide better coverage and protect your eyes from all angles. This style prevents debris from entering the sides of the glasses and ensures maximum protection. Look for glasses with an adjustable nose piece and comfortable temple arms for a secure fit.

Ear Protection

Power tools can generate loud noises that can be harmful to your hearing if exposed for extended periods. Protecting your ears with proper ear protection is crucial. Here are two common types of ear protection:

Earplugs

Earplugs are small, foam, or silicone inserts that fit inside your ears, creating a barrier against noise. They are inexpensive, disposable, and easy to carry around. Earplugs come in various sizes and shapes, so it’s crucial to find the ones that fit your ears properly for maximum effectiveness.

Earmuffs

Earmuffs are another type of ear protection that covers your entire ears. They consist of two ear cups connected by a headband. Earmuffs provide a higher level of noise reduction compared to earplugs and are more suitable for prolonged exposure to loud sounds. Look for earmuffs with adjustable headbands and comfortable padding.

Noise Reduction Rating

When choosing ear protection, consider the noise reduction rating (NRR). The NRR indicates how much the earplugs or earmuffs can reduce the noise level. The higher the NRR, the more effective the ear protection will be in blocking out loud sounds. Choose the ear protection with the appropriate NRR for your specific needs.

Handheld Power Tools

Handheld power tools are versatile and portable, making them ideal for various tasks. They are typically operated with one hand and are commonly used in construction, woodworking, and other industries. Let’s take a closer look at some common handheld power tools:

Drills

Drills are one of the most commonly used power tools. They are versatile and can be used for a variety of tasks, including drilling holes in different materials or driving screws. Drills come in different types, such as corded drills or cordless drills, depending on your needs.

Sanders

Sanders are power tools used for smoothing surfaces by abrasion. They are ideal for removing paint or varnish, shaping wood, or giving final finishing touches to a project. Sanders come in different types, such as orbital sanders, belt sanders, or detail sanders, each designed for specific applications.

Grinders

Grinders are powerful tools used for cutting, grinding, or polishing different materials. They come in different sizes and types, including angle grinders and bench grinders. Grinders are commonly used in metalworking or construction projects to shape or smooth surfaces.

Saws

Saws are essential power tools used for cutting through various materials, including wood, metal, or plastic. They come in different types, such as circular saws, jigsaws, or reciprocating saws, each designed for specific cutting applications. Saws are versatile tools and can be used for a wide range of projects.

Stationary Power Tools

Stationary power tools are larger and are meant to be mounted or placed on a workbench or stand. They provide stability and precision for more controlled and accurate operations. Let’s explore some common types of stationary power tools:

Table Saw

A table saw is a powerful woodworking tool used for making straight cuts in wood. It consists of a circular saw blade mounted on a table with a sliding surface. Table saws are versatile and can be used for various woodworking tasks, including ripping, crosscutting, or mitering.

Bandsaw

A bandsaw is a versatile tool that uses a continuous cutting band or blade. It is commonly used for making curved cuts, intricate designs, or resawing thick lumber. Bandsaws are commonly found in woodworking or metalworking shops and are ideal for precise and intricate cutting operations.

Jointer

A jointer is a woodworking tool used for flattening, straightening, and smoothing the edges of a board. It is particularly useful for creating straight and square edges before joining multiple pieces of wood together. Jointers are commonly used in woodworking projects that require precise and clean edges.

Planer

A planer is a woodworking tool used for smoothing and flattening the surface of a board. It is used to create a consistent thickness across the entire length of the board and is essential for achieving precise and uniform results. Planers are commonly used in furniture making or carpentry projects.

Pneumatic Power Tools

Pneumatic power tools, also known as air tools, are powered by compressed air. They are widely used in various industries due to their power, lightweight design, and durability. Let’s explore some common types of pneumatic power tools:

Air Compressor

An air compressor is the main power source for pneumatic tools. It generates and stores compressed air, which is then used to power other pneumatic tools. Air compressors come in various sizes and capacities, depending on your specific needs. They are commonly used in construction, automotive, and industrial applications.

Nail Gun

Nail guns, also known as nailers, are pneumatic tools used for driving nails into various materials. They save time and effort compared to manual hammering and are widely used in construction or carpentry projects. Nail guns come in different types, including framing nailers, finish nailers, or brad nailers, each designed for specific nail sizes and applications.

Paint Sprayer

Paint sprayers are pneumatic tools used for applying paint or other coatings to surfaces quickly and evenly. They provide a high-quality finish and are commonly used in painting projects that require a large area to be covered efficiently. Paint sprayers come in different types, including airless sprayers, HVLP sprayers, or conventional sprayers, each designed for specific applications.

Proper Tool Handling

Proper tool handling is essential for both your safety and the effectiveness of your work. Here are some tips to ensure safe and efficient tool handling:

Familiarizing with the Manual

Before using any power tool, it is crucial to read and understand the manufacturer’s manual. The manual provides important information about the tool’s features, proper operation, maintenance, and safety guidelines. Familiarize yourself with the manual to ensure you are using the tool correctly and safely.

Inspecting Tools

Inspecting your tools before each use is important to identify any potential issues or defects. Check for any damage, loose parts, or frayed cords that may affect the tool’s performance or safety. Do not use any tool that appears to be damaged or faulty and report it to your supervisor or the appropriate person.

Using Correct Techniques

Each power tool has specific operating guidelines and techniques. Properly using the tool not only ensures your safety but also improves the efficiency and quality of your work. Follow the correct techniques, such as maintaining a firm grip, applying the appropriate pressure, and using the correct accessories or attachments.

Preparing the Work Area

Preparing the work area before starting any project is vital for a safe and organized workspace. Here are some steps to consider when preparing the work area:

Clearing Clutter

Remove any unnecessary items or debris from your work area. Clutter can be a tripping hazard and can obstruct your movement or access to tools or materials. Keeping the area clean and organized promotes a safer and more efficient working environment.

Securing Workpieces

If handling materials or workpieces that require cutting or shaping, ensure they are securely clamped or held in place. Unsecured workpieces can shift or move during the operation, increasing the risk of accidents or producing poor results. Use clamps, vices, or other appropriate tools to secure the workpiece before starting any cutting or shaping process.

Proper Lighting

Good lighting is crucial for ensuring accurate and safe work. Insufficient or poor lighting can lead to mistakes or accidents. Make sure your work area is well-lit, especially in areas where precise measurements or cuts are required. Use additional task lighting if necessary to ensure proper visibility.

Accident Prevention

Accident prevention should be a top priority when working with power tools. Here are some strategies to help prevent accidents in your work area:

Keeping Workspace Clean

Maintaining a clean and organized workspace is essential for accident prevention. Regularly clean up debris, dust, or any spills to prevent slips, falls, or fire hazards. Dispose of waste materials properly and keep the work area free from tripping hazards.

Avoiding Distractions

Stay focused on the task at hand and avoid distractions while using power tools. Distractions can lead to accidents or errors in judgment. Keep your attention on the tool and the workpiece, and avoid using power tools when tired or under the influence of drugs or alcohol.

Creating a Safe Zone

Establishing a safe zone around your work area is important to protect yourself and others. Restrict access to the work area by using barriers, signs, or floor markings. Communicate with your colleagues or bystanders about the potential hazards and ensure they stay outside the safe zone.

Conclusion

When using power tools, prioritizing safety should always be our utmost concern. Wearing the appropriate safety equipment, including protective clothing, safety shoes, safety glasses, and ear protection, is crucial for minimizing the risk of accidents and injuries. Additionally, choosing the right clothing, understanding the different types of power tools, and practicing proper tool handling techniques are essential for a safe and efficient work environment. By following these guidelines and implementing accident prevention strategies, we can ensure a safer and more productive experience when working with power tools.